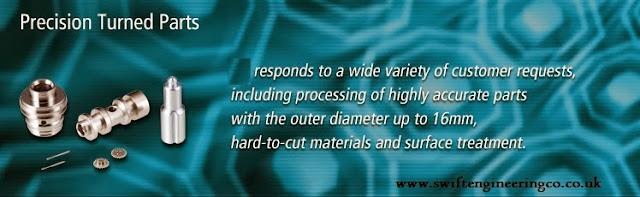

A CNC lathe is a multifaceted lathe designed to cut a

precision turned parts using a diversity of instruments. It can cut an item

made of wood, metal or plastic. Vertical CNC lathes come in several dissimilar

varieties depending on their deliberate use. Selecting the best one is a matter

of considering the works the user desires to complete and the user's financial

plan.

| |

|

Although a vertical CNC lathe can come in a diversity of

sizes and speeds, these lathes are most generally used for critical large or

oddly shaped precision turned parts. One consideration for probable buyers

should be the dimension and thickness of the fabrics they wish to cut. The

superior the objects, the larger the machine should be. A more opaque objects

demands the lathe turn at a superior speed.

The quantity of Precision turned parts that a worker will

cut should be measured as well. While the smaller types of the vertical CNC

lathe are inexpensive for most people, lathes designed to cut big articles can

be very costly. Many machine shops concentrate in taking smaller orders of

tradition cut pieces. This can be a more lucrative way if a person only desires

a few pieces.

If the volume of an industry is elevated enough, then space

on the floor and operating cost can also be cheap by using dual or multiple

spindle vertical CNC lathes.